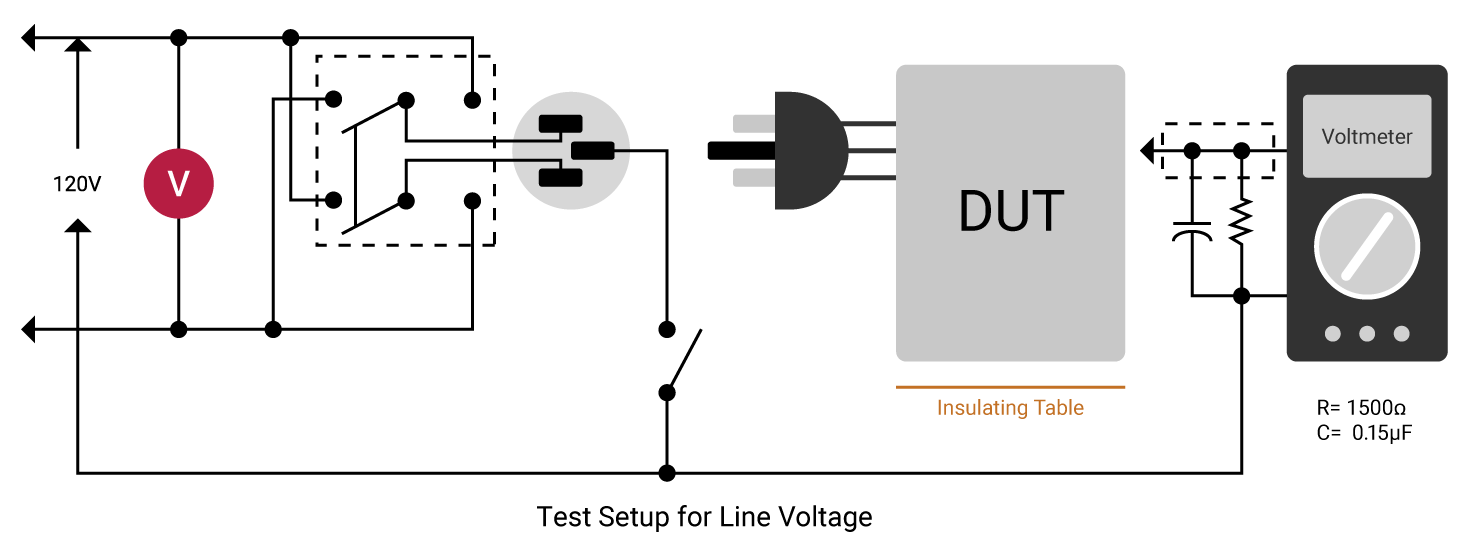

A line voltage leakage current test simulates the effect of a person touching exposed metal parts of a product and detects whether or not the leakage current that would flow through the person’s body remains below a safe level.

A person typically perceives current flow through his body when it reaches or exceeds 1mA (one thousandth of an ampere). Current above the threshold can cause an uncontrolled muscular spasm or shock. An equivalent circuit of the human body consists of an input resistance of 1500 ohms shunted by a capacitance of 0.15 microfarads.

To provide a margin of safety for the consumer, regulatory agencies usually require that a product exhibit a line voltage leakage current of less than 0.5mA. With some products equipped with 3-prong plugs and warning stickers, the permissible leakage current may be as high as 0.75mA, but the typical limit is 0.5mA. Since hipot tests are usually required for 100% of the units in a production line, and since hipot tests are more stringent, line voltage leakage tests are normally specified as design or type tests and not as production line tests. Line voltage leakage tests are typically required on all medical products as a production test.

Line voltage leakage test are conducted with a circuit similar to that shown in Figure 17, measuring the leakage current under various fault conditions such as “no ground” or with line and neutral connections reversed. Voltage is applied first with normal line and neutral connections, followed by a test with the connections reversed, and then with no ground.

The measurement of leakage current is a requirement for type testing of any mains powered product. A compliance laboratory or National Recognized Test Lab (NRTL) normally performs the type testing on a sample of products during the design phase. Once the type testing is complete generally no further leakage testing is required on a production basis with the exception of medial products. Leakage current measurements are routinely performed on the production line for medical products for safety reasons.

UL Values for Leakage Current Limits

| Class | Equipment Type | Maximum Leakage Current |

| II Ungrounded | All | 0.25mA |

| I Grounded | Hand-held | 0.75mA |

| I Grounded | Movablebv(Not hand-held) | 3.5mA |

| I Grounded | Stationary, Type A | 3.5mA |

Types of Leakage Current

There are several different types of leakage current: Earth Line Leakage, Touch/Chassis (formerly Enclosure) Leakage, Patient Leakage, and Patient Auxiliary Current. The basic differences between leakage currents depend upon how a person might come in contact with the product or the measurement. For example the leakage that would flow through a persons body if they touched the outside enclosure of a product would be Touch/Chassis or Enclosure leakage.

- Earth leakage: Line leakage current measured when the ground connector is open, a circuit that simulates the impedance of the human body is inserted and the voltage is measured across it.

- Touch/Chassis (Enclosure) leakage: Line leakage current measured by connecting the circuit that simulates the impedance of the human body to any exposed part of the chassis of the DUT. This simulates someone touching the enclosure/chassis of the DUT.

- Patient (Applied Part) leakage: Line leakage measured from or between applied parts of the DUT such as the current that might flow from patient leads and sensors on a medical device.

- Patient Auxiliary leakage: Line leakage current flowing in the patient in NORMAL use between applied parts of the DUT and not intended to produce a physiological effect.

What is a safe level of leakage current?

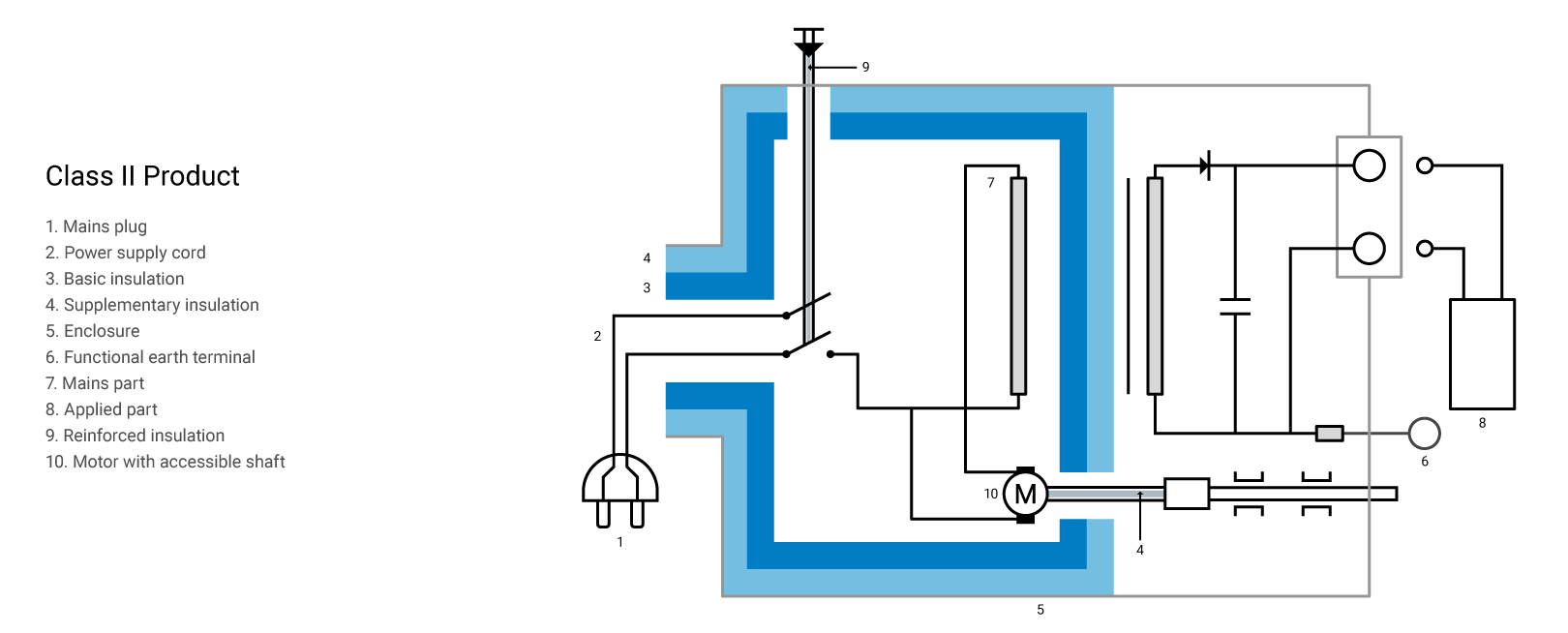

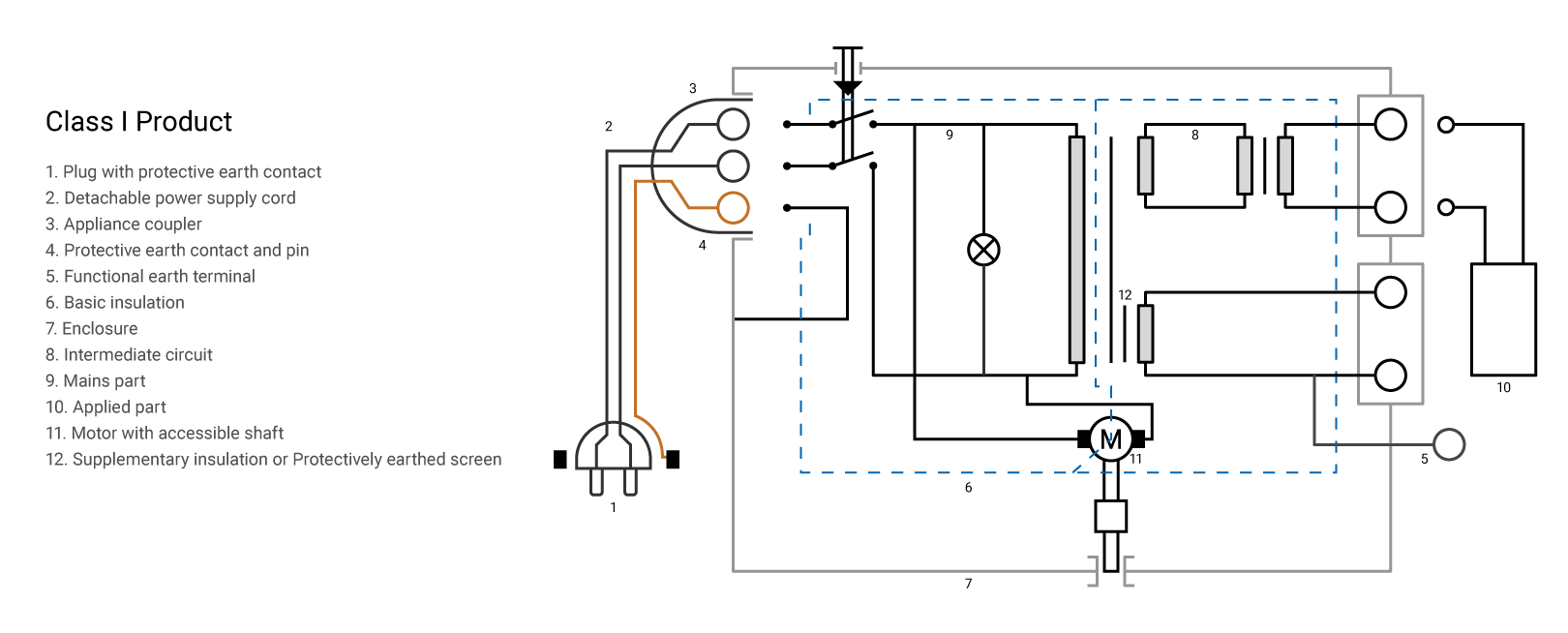

Depending on the type of equipment, acceptable levels of leakage current have been determined and are generally outlined in the appropriate international or regional standard. Acceptable levels of leakage current are dependant on the classification of the particular type of equipment. The basic principle behind protection against electrical shock is to have at least two levels of protection.

Class I

Class I products use Basic Insulation in combination with Protective Earth. These products will have a three-prong power cord and the ground blade will be attached to any accessible metal on the product. Class I products have higher allowable leakage currents as the ground provides a level of protection for the operator and effectively drains off leakage current that a person might come in contact with. Leakage current limits for Class I products also vary depending upon whether the power cord is detachable or permanent.

Class II

Products that have a two-prong power cord are Class II products. Class II products rely not only on basic insulation but also supplemental insulation or reinforced insulation. These products are often referred to as double insulated products as protection against shock relies on two layers of insulation. Since there is no protective earth to drain off excess leakage current the limits of acceptable leakage current for Class II products are lower than Class I products.

Measurement of Leakage Current

The measured leakage current values are then compared with acceptable limits based upon the type of product being tested (class), point of contact with the product (Earth, Touch, Patient) and operation of the product under normal and single fault conditions.

The leakage current measurements are performed with the product energized and in all conditions such as standby and full operation. The mains supply voltage is normally delivered via an isolation transformer to the product.

The mains supply voltage should be at 110% of the highest rated supply voltage and at the highest rated supply frequency. This means that a product rated for operation at 115VAC 60Hz and 230VAC 50Hz would be tested at 110% of 230VAC that equals 253VAC and at a line frequency of 60Hz.

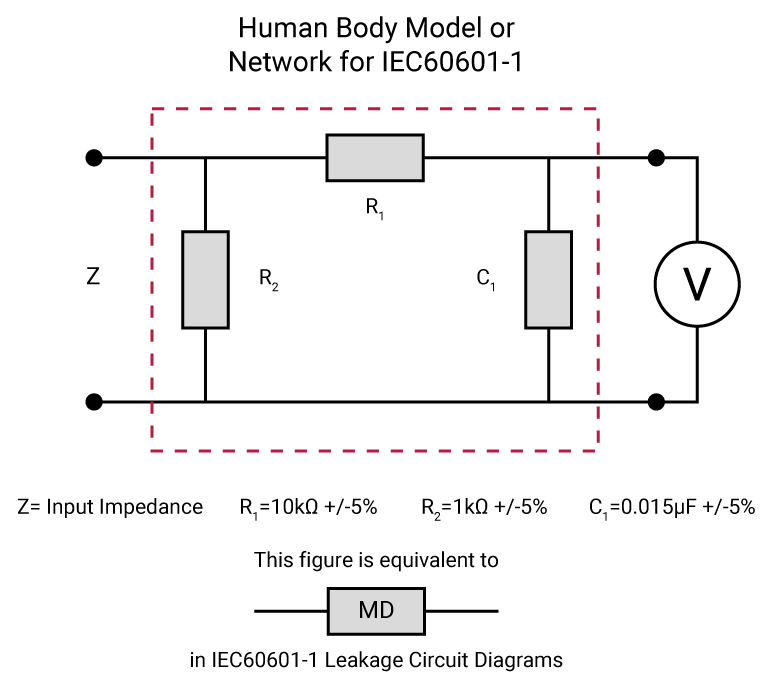

The measuring instrument referred to as MD shall have an input impedance (Z) of 1MW and a frequency characteristic that is flat from DC to 1MHz. Refer to Figure 20. The instrument shall indicate the true R.M.S. value of the voltage across the measuring impedance or the current flowing through the measuring device with an indicating error not exceeding ±5%. The instrument shall also load the source of the leakage current with an impedance of approximately 1000W for frequencies from DC to 1MHz.

This is accomplished by using a human body model or network attached to the input of the measuring instrument. Depending upon the standard being used the impedance of the human body model or network will change. Figure 20 shows a human body model or network used in IEC60601-1 for medical device testing. There are a number of commercially available instruments that are specifically designed to perform leakage current measurements. These instruments have all of the correct accuracy, input impedance and typical selectable human body models for several popular standards built right in to the instrument.

Leakage currents are measured during both normal operation and fault conditions. Normal operation means the product energized in both standby and full operation. Medical devices also have the requirement for connection of any voltage or current permitted under normal operation to the signal input and output parts. Single fault conditions include opening of protective ground and opening of the neutral conductor on the mains supply. There can be additional fault conditions depending upon the design of the product.

There are some general rules that should be followed when performing a leakage current measurement. The product being tested should be placed on an insulating surface and significantly far away, 20cm, from any earthed metal surface. The measurement circuit and cables should be positioned as far away from unscreened power supply leads as possible and significantly far away from any earthed metal surface. Refer to our Application Notes library for additional information on Leakage Current Testing for Medical Products.