• Engineering Characterization & Design Validation

• High Volume Production

• Vendor Qualification & Incoming Inspection

• Depot Repair & Failure Analysis

• Custom Test Fixtures & Test Programs

• Global Operations & Worldwide Support

• Local & International Program Management

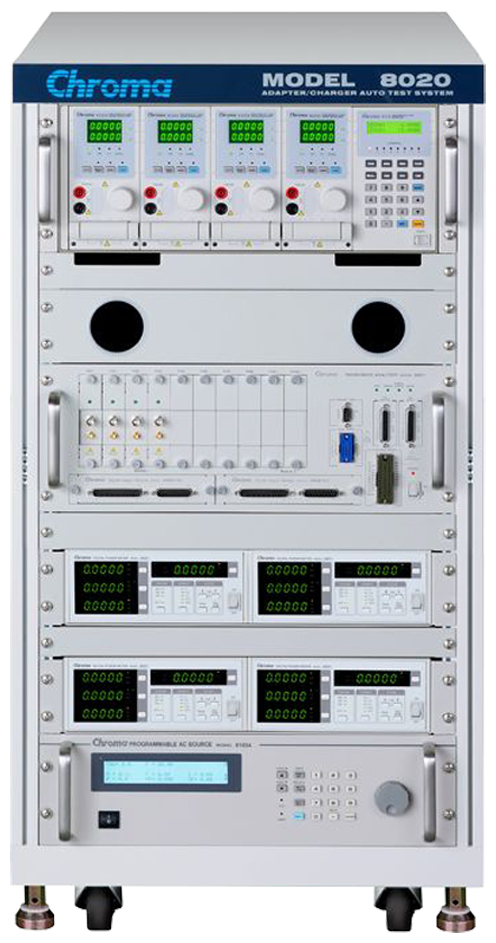

• Widest Selection of High Precision Test Instrumentation

• Highly Customizable Configurations & UUT Interfaces

• Extensive Comm. Support: CAN, LAN/ Ethernet, I2C, PMbus, USB, GPIB, Serial, etc.

• Individual Instrumentation Display Panels & Controls Simplifies Debugging

• Supports Complex Inter-Instrument Triggering

• Optimized for High Throughput Testing

• Dynamically Configurable for R&D Engineering & Design Validation

• Enterprise Wide Open Architecture Platform

• Custom Reporting with Waveforms & Graphs for Engineering R&D & Design Validation

• Fast & Easy, Excel Like Test Sequence Development

• Comprehensive Test Library

• Customer Editable Test Library Without Coding

• Statistical Reporting

• Command Optimizer Maximizes Test Speed

• A/B & Parallel Testing for High Volume Applications