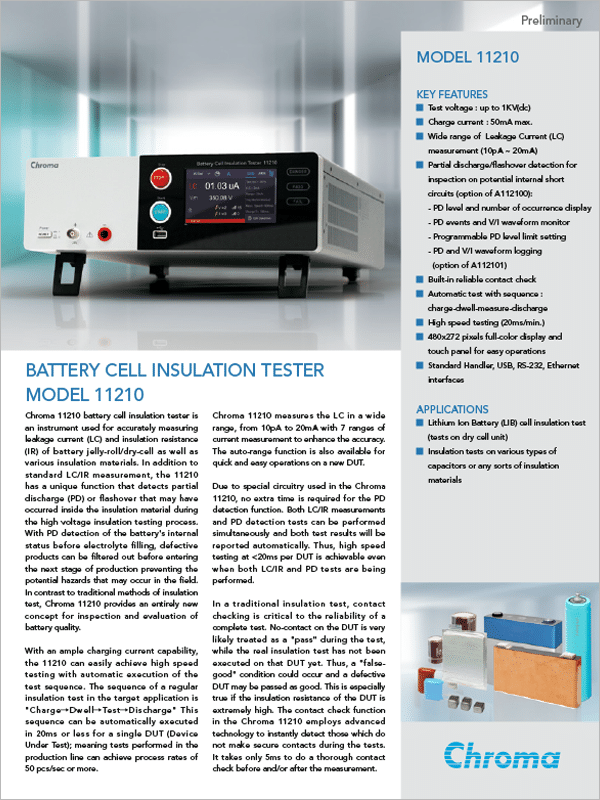

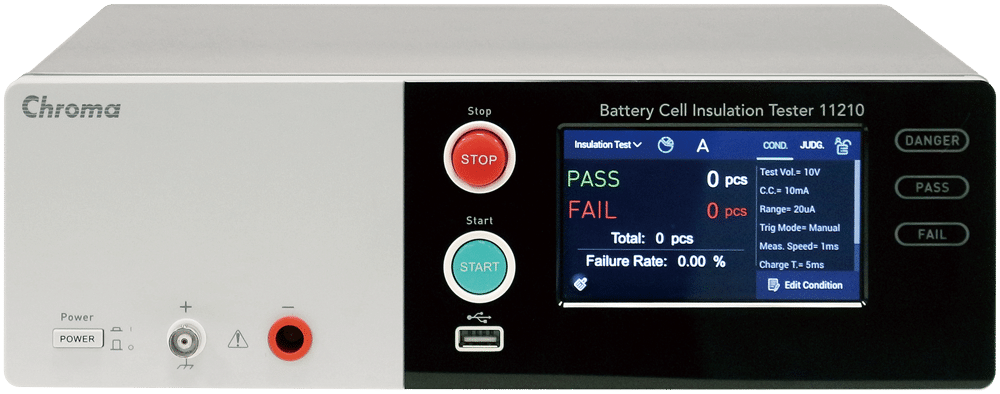

Exploring Battery Cell Insulation Tester

Battery Cell Insulation Tester

Chroma 11210

Accurately measure leakage current (LC) and insulation resistance(IR) of battery jelly-roll/dry-cell as well as other insulation materials.

Test Voltage

Up to 1KV(DC)

Charge Current

50mA max.

IR (Insulation Resistance)

0.01kΩ~10 TΩ [kΩ, MΩ, GΩ]

Chroma 11210 battery cell insulation tester is an instrument used for accurately measuring leakage current (LC) and insulation resistance(IR) of battery jelly-roll/dry-cell as well as other insulation materials. In addition to standard LC/IR measurement, the 11210 has a unique function that detects partial discharge (PD) or flashover that may have occurred inside the insulation material during the high voltage insulation testing process.

PD Detection and Measurement Function

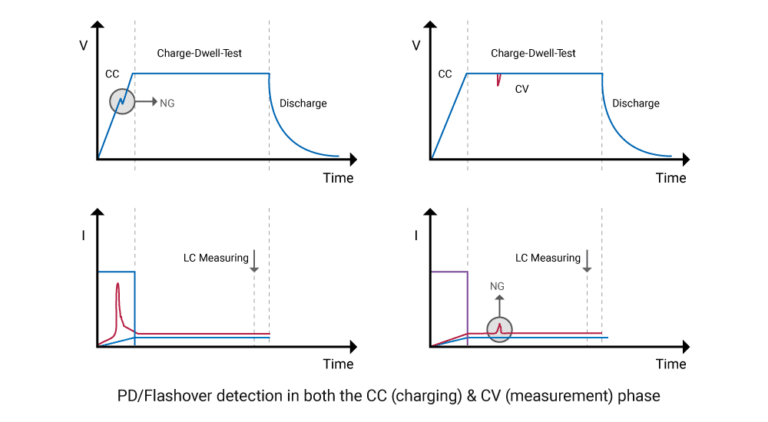

Chroma 11210 battery cell insulation tester detects any PD or flashover that may occur inside the battery cells. There are two phases of detection that the 11210 employs with different circuitries used. The first phase is in CC (Constant Current) mode when the 11210 charges the DUT with a constant current set by the user. During this mode, the 11210 will monitor the voltage level and its slope. Any glitches on the voltage slope or any unexpected changes of the slope will be detected by the 11210 and reported as PD occurrences.

The second phase is in CV (Constant Voltage) mode. In this mode, only a stable leakage current should exist. Thus any unusual and protruding pulses on the current waveform are typically the result of an abnormal discharge (i.e. PD or flashover) which will also be detected and reported by the 11210 as a PD occurrence. Chroma 11210 not only detects, but also roughly measures the magnitude of the PD pulses during these modes.

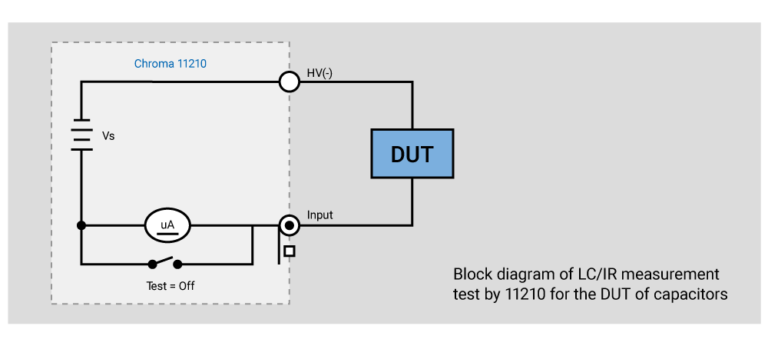

Capacitor Test Applications with 11210

Chroma 11210 is the next generation and advanced version of its predecessor the Chroma 11200 capacitor LC/IR meter. The 11210 includes more versatile functions with higher accuracy, however, retains all the major functions and capabilities found in the 11200. Therefore, the 11210 is also an advanced LC/IR meter for all types of capacitors. In the production line, the 11210 is able to test capacitors at a very high speed (~20ms per DUT) with appropriate fixtures.

Moreover, it has a very wide range of LC/IR measurement with excellent accuracy. Chroma 11210 is the new standard insulation inspection and test instrument for all capacitor production lines.

More Features

Automatic Test with Sequence: Charge-Dwell-Measure-Discharge

High Speed Testing

(20ms/device)

Full-Color Display

and Touch Panel

Handler, USB, RS-232,

Ethernet Interfaces

With PD detection of the battery’s internal status before electrolyte filling, defective products can be filtered out before entering the next stage of production preventing the potential hazards that may occur in the field. In contrast to traditional methods of insulation test, Chroma 11210 provides an entirely new concept for inspection and evaluation of battery quality.

Model Options

| Model | Description |

| 11210 | Battery Cell Insulation Tester |

| A112100 | Partial Discharge Detection Card |

| A112101 | Partial Discharge Analyzer Card |

| A112102 | PD Test Checking Kit |

| A112103 | Handler Interface Converter Box |

Watch

A Better Insulation Test: Decreasing Risk of Electrical Shorts in Lithium Ion Battery Cells

This seminar covers new testing procedures and equipment to monitor voltage and current in order to detect minor partial discharge or flashover inside the cell resulting in lower risk to the manufacturer and end user.

BDV & PD Functions

This video takes you through the various BDV and PD functions and settings that the 11210 Battery Insulation Tester features.

Improve Li-ion Battery Safety

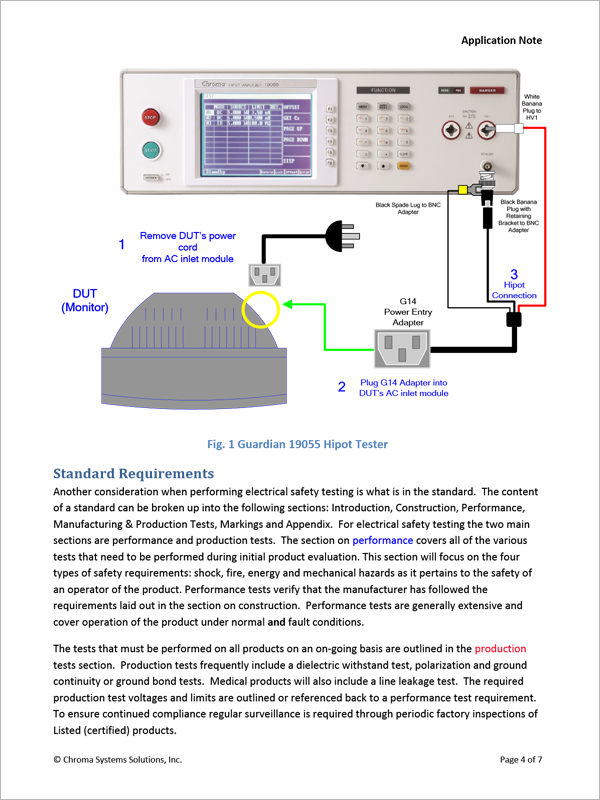

Testing with basic hipot or insulation resistance test instrumentation does not provide any indication to whether the space between the electrodes is safe enough to undergo the charge/discharge cycles of the battery. Partial Discharge (PD) detection in addition to insulation resistance testing, like what’s found in the Chroma 11210, could detect those defects in the dry cell stage prior to electrolyte filling. Detecting burrs or particles early in the production phase allow for these cells to be filtered out before shipment. This can greatly increase product quality, reduce failures, and mitigate any danger that may come from an internal electrical short.

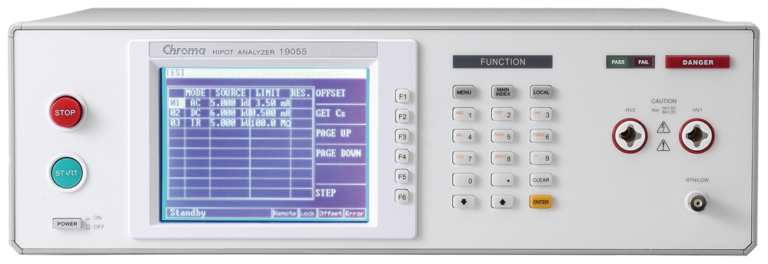

Battery Cell Insulation Tester

Chroma 11210 Battery Cell Insulation Tester detects abnormal insulation of lithium-ion batteries (dry cells), offering two unique technologies that other available withstand voltage or insulation testers lack. First, the test device not only monitors the entire test process for electrical flashover due to abnormal partial discharge but also quantifies it and creates recordable waveforms. Moreover, after reaching the test voltage, the leakage current or insulation resistance are measured and judged during the test time as with WV/IR testers.