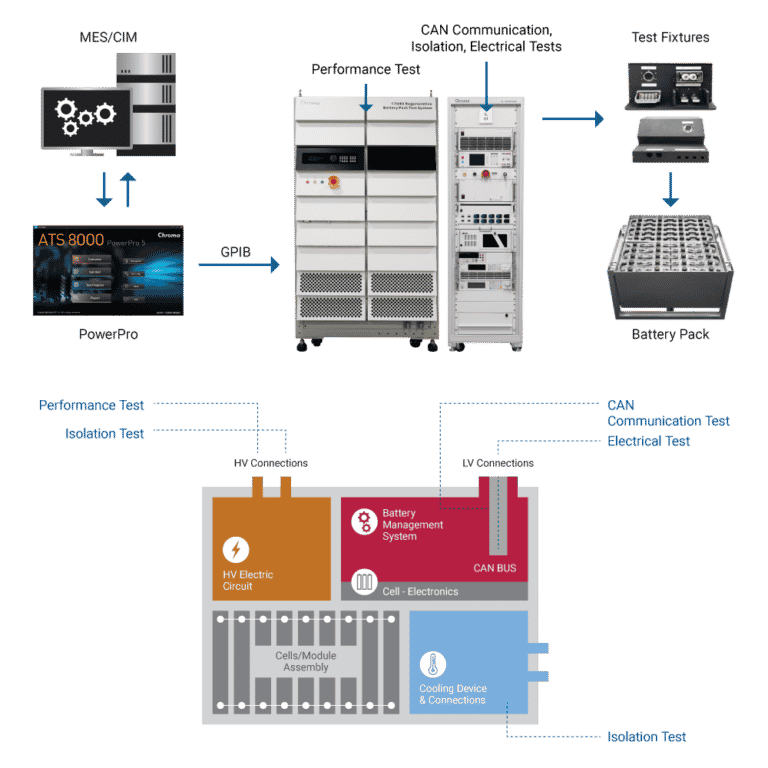

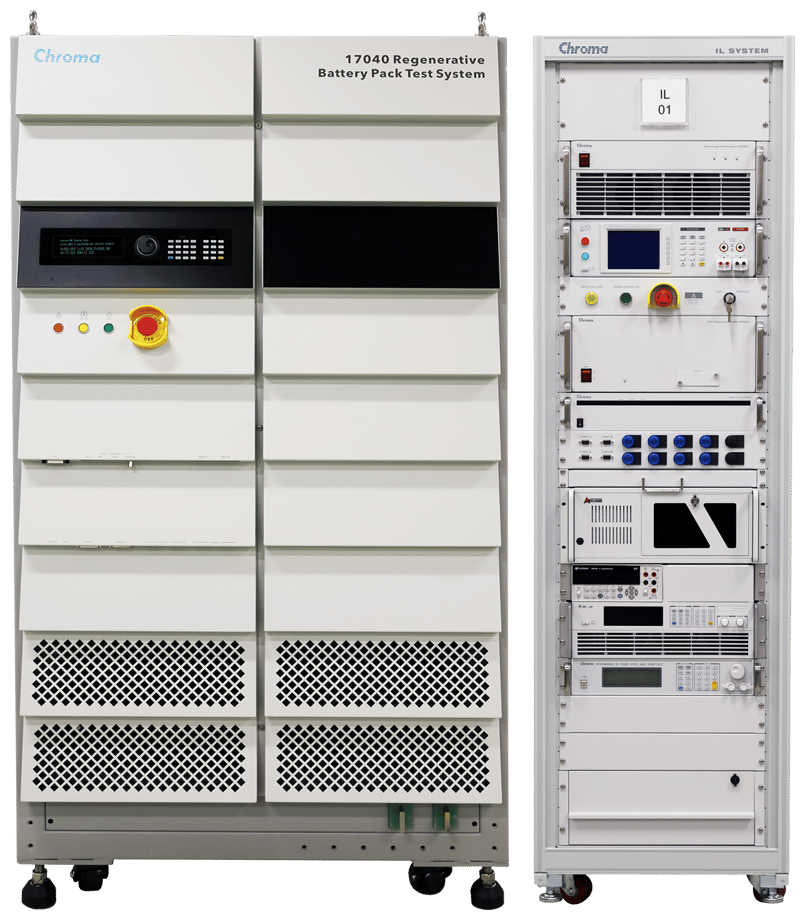

Exploring Battery Pack ATS

Battery Pack ATS

Chroma 8720

Test the battery packs in end of line (EOL) production for a comprehensive Pass/Fail check, including mechanism assembly, pressure insulation, BMS communication, internal high voltage relay parts, battery balance, and temperature distribution, etc.

Charge/Discharge Power Range

5kW ~ 350kW

Charge/Discharge Voltage Range

0V~900V

Charge/Discharge Current Range

0A~1000A

In order to increase testing coverage and the efficiency of the power storage battery industry, Chroma ATE has developed an automated inspection system that can be applied to the EOL (End Of Line) of battery packs production for testing the assembly defects, Battery Management System (BMS) communication, internal power switches, battery balancing circuits/consistency, and temperature distribution, etc. before battery packs are shipped out of the factory.

Key Features

- Specifically designed for battery production line or battery development testing

- Increases QA efficiency by up to 80%

- Inspection of BMS functions, connector withstand voltage, consistency, and performance of battery module

- Standard test items include insulation resistance, electricity, software/communication, and battery performance testing

- Able to create the fixture to connect the customized battery module with automated switch control

- Easy-to-use open software platform that can support shop floor control and could integrate with Manufacturing Execution System (MES)

Standard Function Test Items

(1) Isolation Test:

- Terminal(HV+, HV-) insulation resistance

- Ground isolation

- Shield impedance

- Hi-Pot test

(2) Electrical Test:

- HV interlock fuction test

- Max. and Min Voltage/Temperature range test

(3) CAN Communication Test:

- Cell and Pack voltage/Temperature

- Contactor characterization

- Diagnostic trouble and fault mode test

(4) Performance Test:

- Standard charge/discharge capacity test

- Drive profile cycle test

- DCIR / OCV test