Exploring Regenerative DC Electronic Load

Regenerative DC Electronic Load

Chroma 63700

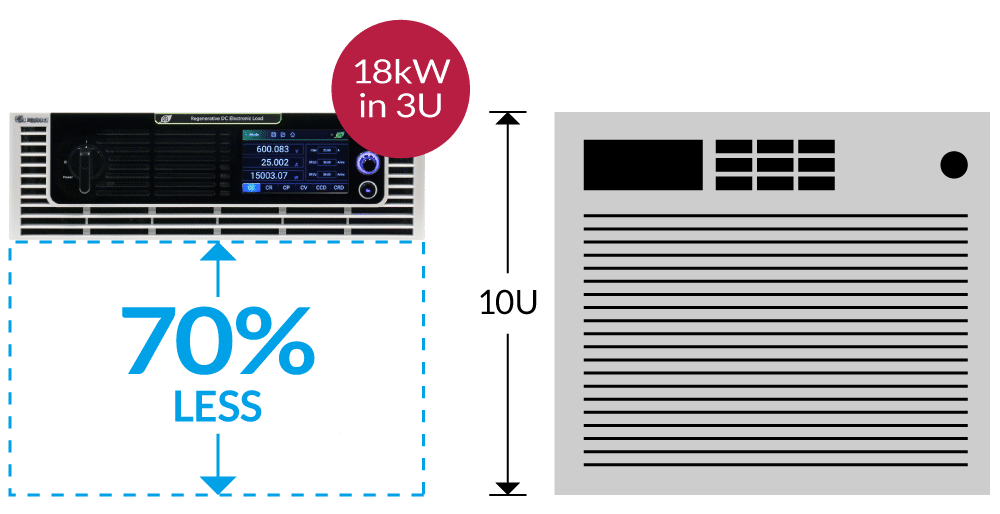

Offers high power density within a compact 3U form factor, with power ratings reaching up to 18kW per unit and currents of up to 120A.

Rated Power:

6kW, 12kW, 18kW

Voltage Range

600V, 1,200V, 1,800V

Current Range:

Up to 120A

Chroma 63700 Series Regenerative DC Electronic Loads are suitable for product reliability testing in various applications, including electric vehicle (EV) battery discharge, fuel cell discharge, high-power power supply aging, DC EV supply equipment (EVSE), unidirectional on-board chargers (OBC), fuel cell systems, energy storage systems (ESS), AC/DC and DC/DC power supply burn-in tests, and various power electronics applications.

These regenerative DC loads can simulate a wide range of load characteristics while also feeding energy back to the grid, providing an efficient and sustainable solution that reduces test environment temperatures, HVAC power consumption, and power conversion electricity costs.

The 63700 Series offers high power density within a compact 3U form factor, with power ratings reaching up to 18kW per unit and currents of up to 120A. Users can parallel up to 10 units* for a maximum power of 180kW and a maximum current of 1,200A. Voltage options include 600V, 1,200V, and 1,800V.

All models in the series come equipped with external signal control functionality*, allowing for the simulation of real current waveforms. Master/slave control enables parallel operation of identical 63700 units for synchronized dynamic loading. The system can store up to 256 programmable sequences*, which can be loaded at any time, reducing test duration and increasing throughput during automated testing.

Regarding measurement capabilities, the 63700 Series can perform real-time and precise voltage and current measurements. With the TFT touch display and rotary knob on the front panel, the 63700 Series offers convenient operation and setup. These units can also be controlled via LAN, USB, GPIB, or CAN.

Additionally, the 63700 Series features over-current, over-power, and over-temperature protection functions, as well as an over-voltage alarm mechanism, ensuring product reliability during testing. These attributes make it an ideal test solution for design verification and integration into automated test systems.

Application

Chroma 63700 series of regenerative electronic loads achieve a maximum energy recovery efficiency of up to 93%. Furthermore, they feature high power density, effectively reducing their size and saving space. These loads are well-suited for long-term reliability testing applications across various power sources, including vehicle DC charging stations, unidirectional on-board chargers, automotive battery discharging, fuel cell discharging, and more. By connecting them in parallel, the 63700 series can reach a maximum power of 180kW, making it suitable for power requirements ranging from 5kW to 180kW.

- DC EVSE Stability Testing

- Single/Bidirectional Onboard Charger Stability Testing

- EV Battery Discharge Testing

- AC/DC & DC/DC Converter Life Cycle Testing

- Server & Communication Power Supply Reliability Testing

- Energy Storage System Discharge Testing

- Fuel Cell Discharge Testing

- Power Electronic Components Inspection or Reliability Testing

- Solar Array Load Testing

Key Features

Energy Recovery

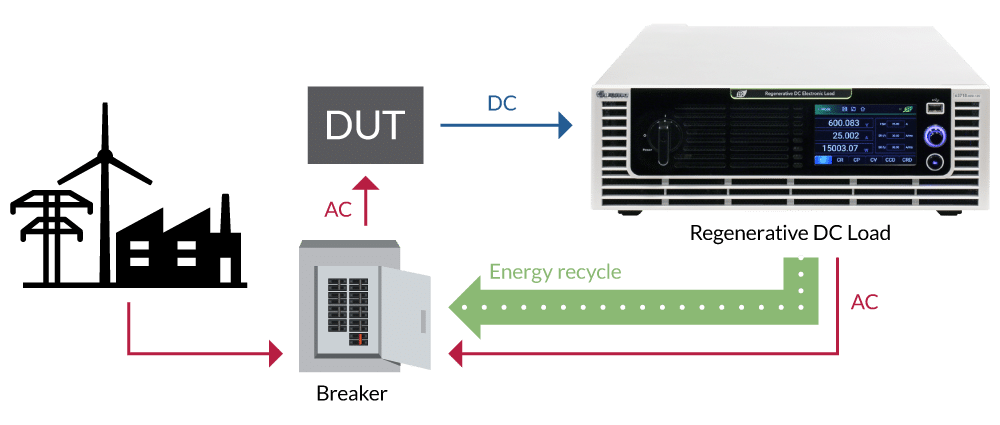

The 63700 series features energy recovery DC electronic loads that efficiently convert the consumed electrical energy into AC current and feed it back into the power grid, achieving an impressive efficiency of up to 93%. The reclaimed electrical energy can be utilized by other equipment within the facility, leading to savings in overall energy consumption and reduced carbon emissions, thereby lowering the environmental impact. This approach also effectively reduces the heat generated by the electronic loads during operation, subsequently decreasing air conditioning energy consumption and cutting electricity costs.

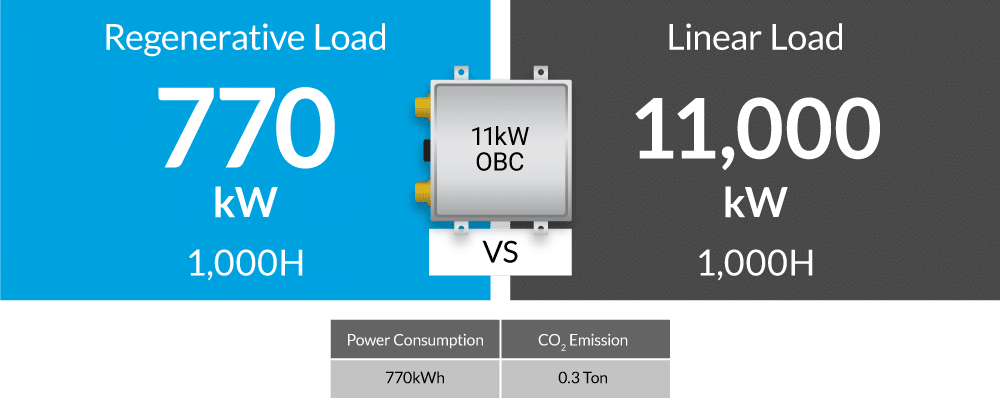

Example 1: 1,000-hour reliability test with an 11kW On-Board Battery Charger (OBC)

The conventional electronic load consumes about 11,000kWh during the test. By contrast, the regenerative load consumes about 770kWh, saving as much as 10,230kWh.This translates to about USD 1,759 worth of energy savings and 3.95 tons of reduced carbon emissions.

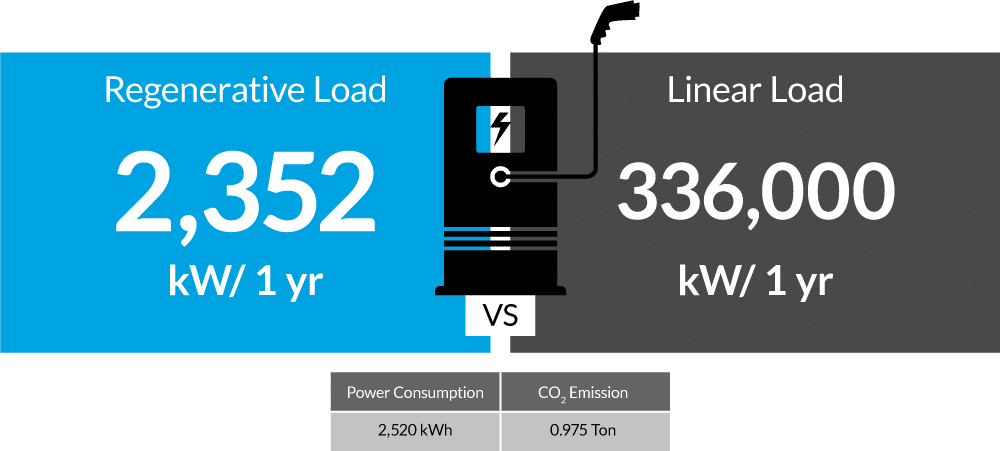

Example 2: Production of a 30kW EV Charging Station Power Module

During the production process, the average output power of the module is 5kW. Production runs for 20 hours a day, 30 days per month. When testing with a conventional electronic load, the annual energy consumption is approximately 36,000kWh, resulting in carbon emissions of around 13,932 kilograms. With a regenerative load, the annual energy consumption is approximately 2,520kWh, resulting in carbon emissions of about 975 kilograms. This leads to a reduction of about 12.96 metric tons of carbon emissions.

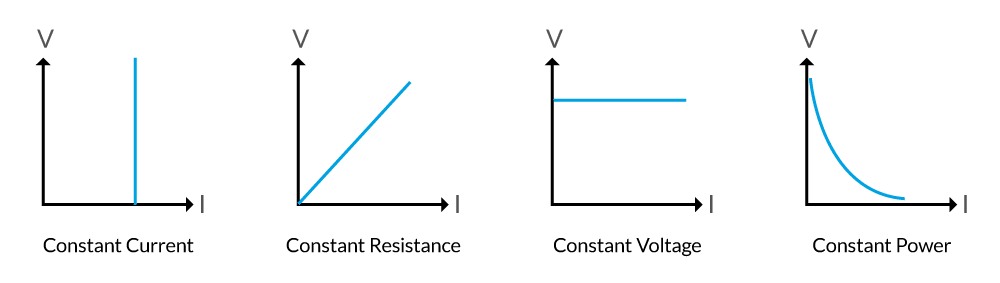

Basic Mode

The 63700 series offers constant voltage (CV), constant current (CC), constant resistance (CR), and constant power (CP) modes of operation to meet various test requirements. For example, in the CC and CR modes, when testing the voltage source DUT (Device Under Test), the load can be used to verify whether the DUT’s output voltage remains stable under different load conditions. For On Board Charger (OBC), battery chargers or charging stations, when the charger operates in constant current mode, the 63700 uses constant voltage mode to simulate voltage fluctuations in the charging battery, ensuring the accuracy of the charging current at the set output voltage of the charger. When the test object is a battery, the electronic load can be set to constant current or constant power mode for discharging the battery. Many battery testing applications, power consumption, and other conditions can be tested using these two modes of the electronic load.

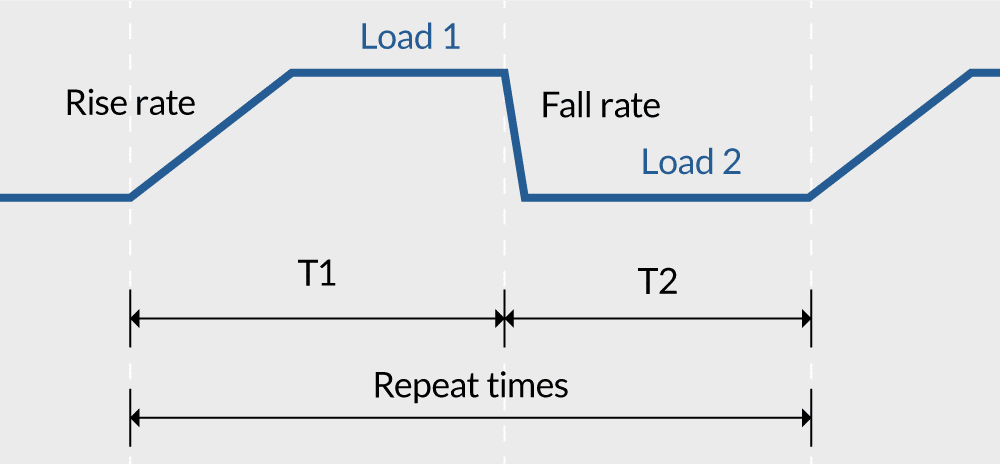

Dynamic Mode

The 63700 Series offers a programmable Dynamic Load (Dynamic Current Load CCD) mode, as illustrated in the diagram below. The programmable parameters include setting the high/low current levels, T1/T2, rise rate/fall rate, and the number of executions. In addition to the mentioned basic parameters, users can also configure a repeat count for a specified duration, with a range of 1 to 65,535.

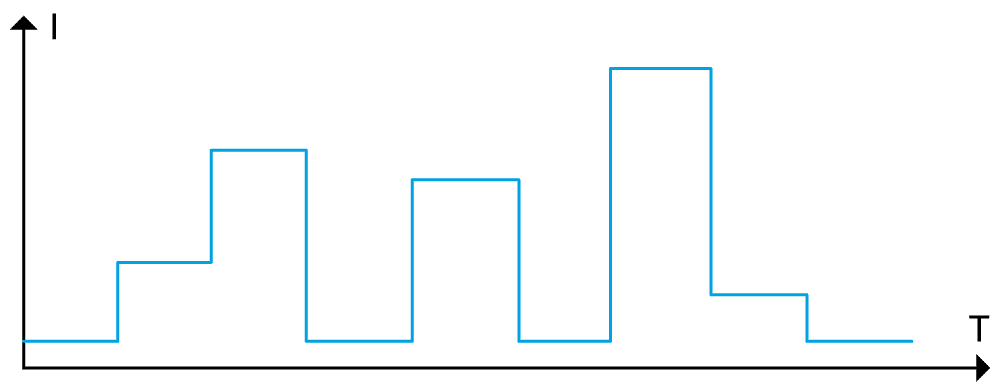

Programmable Load Sequences

The 63700 Series comes pre-equipped with 256 programmable load sequences, allowing users to simulate a wide range of real-world load conditions. One of the examples of common applications for programmed load sequences is: Battery discharge and other applications (such as laptops, electric cars, and electric scooters): Simulate different current waveforms of dynamic loads, providing dynamic current simulation with two or more current levels or one-shot load simulation.

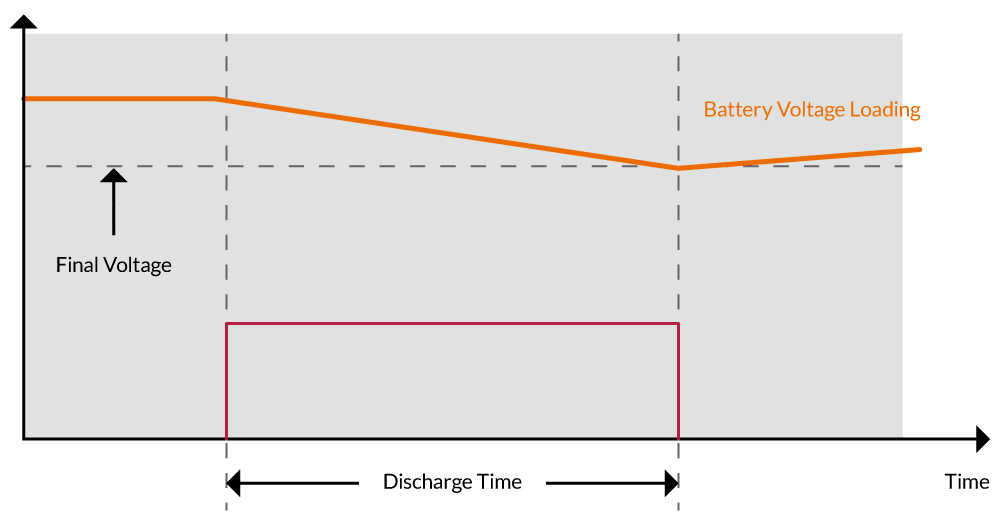

Battery Discharge Testing

Batteries are typically shipped from the factory with a capacity maintained at around 30% to 50%. When the battery capacity exceeds a user-defined percentage during production, it needs to be discharged before shipping. The 63700 Series offers users three discharge test modes: constant current (CC), constant resistance (CR), and constant power (CP). By setting the cutoff voltage and stop time (1 second – 100,000 seconds), the load ensures proper termination of the load to prevent over-discharging and potential damage to the battery. In terms of measurement, the device can measure the discharge energy (WH), discharge capacity (AH), and total discharge time of the battery.

Intuitive Touchscreen and Interface

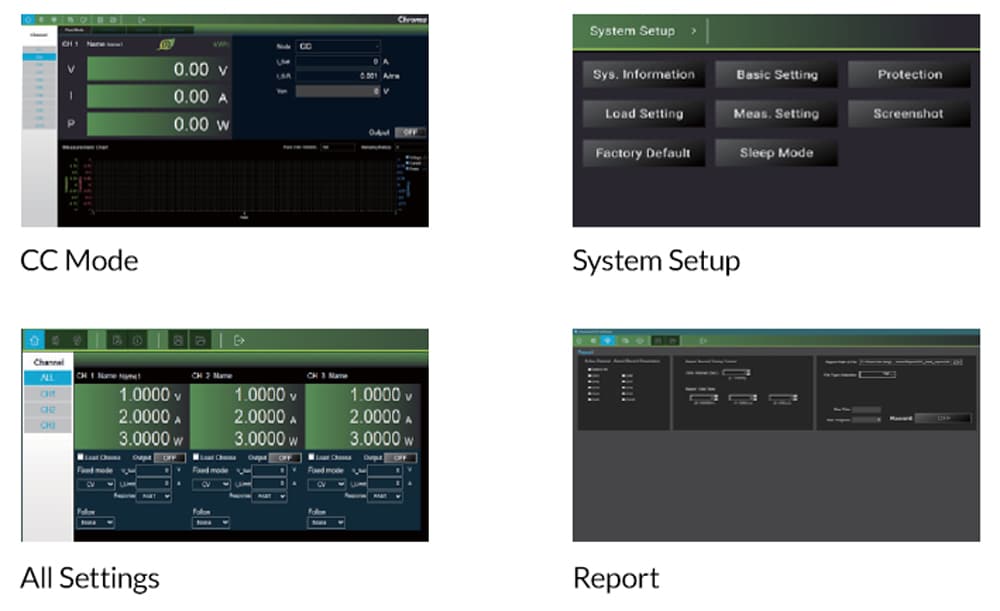

The device features a convenient 5” color touchscreen that simultaneously displays measurement values and settings. An extra physical control knob and load ON/OFF key allow for precise and quick fine-tuning. This combination of touch and analog control options ensures a seamless and intuitive user experience.

The 63700 regenerative load supports various communication interfaces for user control. It comes standard with USB and LAN, and optional GPIB for PC connectivity. Additionally, it features a CAN interface, commonly used in the automotive industry and compliant with CAN2.0 A&B specifications for 11-bit/29-bit frames. This interface allows for high-speed reading of voltage, current, and power parameters with a 10ms response time.

In addition to the front panel, the 63700 Series can also be controlled through Chroma’s SoftPanel graphical software interface. This user-friendly interface includes an array of functions which help users get started quickly and operate the load conveniently. The 63700 Series features multiple interfaces such as GPIB, USB, and LAN, allowing users to choose the interface that best suits their needs when using a PC to operate the unit.

Model Options

| Model | Description |

| 63706-600-40 | Regenerative DC Load 600V/40A/6kW |

| 63712-600-80 | Regenerative DC Load 600V/80A/12kW |

| 63718-600-120 | Regenerative DC Load 600V/120A/18kW |

| 63712-1200-40 | Regenerative DC Load 1200V/40A/12kW |

| 63718-1200-40 | Regenerative DC Load 1200V/40A/18kW |

| 63718-1800-40 | Regenerative DC Load 1800V/40A/18kW |

Watch

Electronic Loads: Features and Benefits

This seminar highlights key features and functions of our DC electronic loads and the many applications they are being used for all over the world.

Related Products

Modular DC Electronic Load LED Simulator

Chroma 6310/A

200W/30W & 250W/300W/600W/1200W

0~500V

0~20A

Simulate LED characteristics with increased bandwidth to allow for PWM dimming testing; Ideal for the test and evaluation of multi-output AC/DC power supplies, DC/ DC converters, chargers and power electronic components